How Welding Inspection Works: A Comprehensive Guide for Professionals

Welding evaluation plays an important role in ensuring the security and integrity of bonded frameworks. It includes a methodical strategy that consists of both aesthetic examination and progressed screening methods. Specialists need to acquaint themselves with key criteria and regulations regulating the industry. Comprehending the common flaws that can develop throughout welding is crucial. This overview will explore these elements carefully, giving understandings right into the procedures that copyright high quality and honesty in welding.

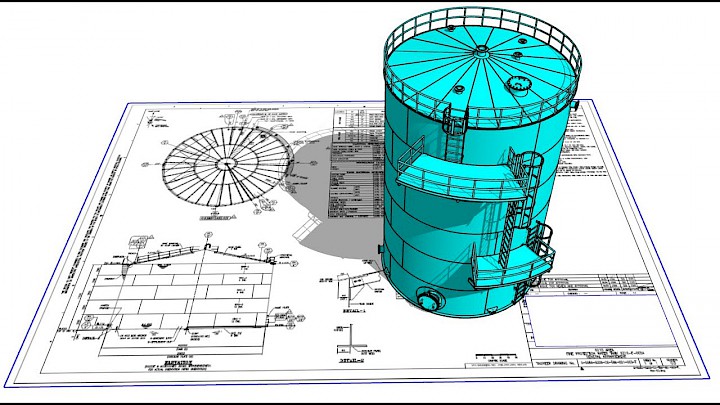

Recognizing the Significance of Welding Examination

While numerous might ignore the value of welding evaluation, it plays a crucial duty in making sure the honesty and safety of welded frameworks. Effective welding inspection determines prospective problems and flaws that can jeopardize architectural strength and result in disastrous failures. The inspection procedure incorporates different strategies, such as visual evaluations, ultrasonic screening, and radiographic analyses, each adding to the overall assessment of weld top quality.

Along with safeguarding the structural honesty, welding examination ensures compliance with industry requirements and client specifications. By guaranteeing that welds meet required attributes and resistances, inspections aid preserve the integrity and longevity of elements in various applications, from building and construction to aerospace. In addition, an extensive evaluation procedure promotes a culture of top quality and responsibility among producers and welders. Ultimately, welding inspection is not simply a procedural action; it is a vital method that underpins the safety and security and efficiency of engineered systems across varied markets.

Trick Specifications and Rules in Welding Examination

The foundation of efficient welding assessment relaxes on adherence to developed requirements and guidelines. Different companies, such as the American Welding Society (AWS) and the American National Requirement Institute (ANSI), established forth guidelines that guarantee high quality and security in welding methods. Key standards, such as AWS D1.1 for structural welding and ASME Area IX for pressure vessels, give thorough standards for welding assessments, procedures, and certifications. Governing structures, including those from the Occupational Safety And Security and Health And Wellness Management (OSHA), mandate safety practices and worker protections in welding settings. Compliance with these criteria is vital for achieving regular weld top quality and reducing the danger of failings. In addition, worldwide requirements like ISO 3834 better enhance international consistency in welding examination methods. Specialists should remain notified regarding these regulations to assure that their inspection approaches line up with market expectations and lawful demands, thereby protecting both workers and structural stability.

First Prep Work and Aesthetic Examination Techniques

Reliable welding inspection begins with a complete pre-inspection list that assures all necessary conditions are met prior to the actual assessment happens. Following this preparation, visual flaw recognition plays a vital role in assessing weld quality, permitting examiners to find problems such as splits or incorrect combination. With each other, these methods create the structure for an effective welding assessment process.

Pre-Inspection List

Before starting any kind of welding examination, a thorough pre-inspection list is important to ensure that all needed prep work are finished and that aesthetic examination strategies are efficiently employed. Crucial element of this checklist consist of validating the welding treatment specification (WPS), making sure all devices is adjusted and in excellent functioning problem, and validating that the assessor has the required accreditations. In addition, it is essential to assess any type of previous examination records and to assess the job setting for security risks. The examiner should likewise confirm that all appropriate paperwork, such as material certifications and assessment documents, is easily available. Finishing this list assists to establish a strong structure for an effective examination procedure, improving the reliability of the outcomes acquired.

Visual Issue Recognition

An effective aesthetic problem identification procedure starts with cautious initial prep work and the application of well established visual assessment techniques. Assessors ought to assure that the welding location is clean and well-lit, as appropriate exposure is vital for identifying problems. A thorough exam of the weld get redirected here joint's surface permits the recognition of gaps, such as cracks, undercuts, or porosity. Inspectors typically make use of tools like amplifying glasses or mirrors to improve their sight of hard-to-reach areas. Additionally, they need to be familiar with the specific welding criteria and guidelines relevant to the task. By adhering to these approaches, inspectors can efficiently determine prospective concerns, safeguarding the honesty of the weld and conformity with industry standards.

Non-Destructive Screening Techniques: An Introduction

Non-destructive testing (NDT) methods play a crucial duty in the welding inspection process by making certain the integrity and dependability of bonded structures without causing any kind of damages (API 650 Welding Inspection). These strategies permit inspectors to assess the high quality of welds while preserving the parts being taken a look at. Typical NDT methods consist of ultrasonic testing, radiographic testing, magnetic particle screening, and dye penetrant screening, each offering unique benefits

Ultrasonic screening employs high-frequency acoustic waves to identify inner imperfections, while radiographic screening uses X-rays or gamma rays to imagine the interior framework of welds. Magnetic fragment testing exposes surface area and near-surface issues by applying a magnetic field and iron bits to the weld location. Color penetrant testing highlights surface-breaking defects with the application of a colored color. Together, these NDT methods offer vital understandings into weld top quality, allowing professionals to make educated choices concerning security and compliance in welding applications.

Common Issues and Their Implications

Determining usual defects in bonded joints is necessary for keeping structural integrity and safety. Numerous issues can emerge during the welding procedure, each carrying possible effects for the general performance of the framework. Porosity, identified by little gas pockets within the weld, can weaken the joint and endanger its load-bearing capacity. Splits might develop due to thermal stress and anxiety or incorrect air conditioning, causing potential failing under anxiety. Incomplete fusion happens when the weld metal does not totally bond with the base product, resulting in weak joints that may not hold up against desired loads. Undercutting, where the base metal is deteriorated, can additionally decrease the reliable cross-section of the weld. Additionally, extreme support can develop stress focus that their explanation can result in failing. Recognizing these defects quickly enables restorative procedures, making sure the durability and dependability of welded structures in vital applications.

Devices and Equipment Used in Welding Inspection

Efficient welding examination depends on a selection of specialized tools and tools to ensure the quality and integrity of welded joints. Vital tools include aesthetic examination devices, such as amplifying glasses and borescopes, which permit inspectors to carefully check out welds for surface flaws. Non-destructive testing (NDT) techniques, such as ultrasonic screening, radiographic testing, and magnetic bit screening, are basic for identifying inner imperfections without harming the material.

Measurement tools, consisting of calipers and weld determines, aid examine measurements and determine conformity with specifications. In addition, hardness testers examine the mechanical buildings of welded joints. Individual protective tools (PPE) is likewise critical, securing the safety and security of assessors while working in potentially harmful environments (API 650 Welding Inspection). Each tool serves a specific function, jointly boosting the effectiveness of welding assessment and adding to the reliability of finished tasks

Frequently Asked Inquiries

What Certifications Are Required to End Up Being a Welding Inspector?

To end up being a welding inspector, people usually require relevant certifications, such as AWS CWI or CSWIP, together with experience in welding processes, design concepts, and understanding of assessment techniques, safety criteria, and relevant codes.

Just How Usually Should Welding Inspections Be Performed?

Welding evaluations need to be conducted regularly, ideally at numerous job stages, consisting of pre-weld, during-weld, and post-weld. Frequency might also depend upon industry criteria, task specs, and the complexity of the welds involved.

Can Welding Defects Be Fixed After Examination?

Yes, welding issues can commonly be repaired after inspection. Depending upon the intensity and kind of problem, proper approaches such as revamping or added welding might be utilized to bring back architectural stability and safety and security compliance.

What Industries Require Normal Welding Examinations?

Numerous markets, consisting of building, production, aerospace, and automobile, call for regular welding inspections - API 650 Welding Inspection. These assessments guarantee adherence to security standards and quality assurance, decreasing risks connected with structural integrity and functional performance in welded parts

Just how Do I Select a Welding Assessment Solution?

To select a welding assessment solution, one need to think about certifications, experience, certifications, and industry track record. Furthermore, reviewing consumer evaluations and guaranteeing the service fulfills appropriate standards can aid assure top quality evaluations and trusted results.

While several might undervalue the significance of welding inspection, it plays a vital role in making certain the stability and safety and security of welded frameworks. Key standards, such as AWS D1.1 for architectural welding and ASME Area IX for pressure vessels, give detailed requirements for welding treatments, evaluations, and credentials. Efficient welding evaluation begins with an extensive pre-inspection list that ensures all needed problems are satisfied before the actual examination takes location. Before commencing any type of welding assessment, a detailed pre-inspection list is essential to ensure that all check it out essential prep work are completed and that aesthetic evaluation techniques are effectively utilized. Non-destructive testing (NDT) techniques play an essential role in the welding examination procedure by making certain the stability and dependability of welded frameworks without triggering any kind of damage.